ConveyorDesigns Inc.

Engineered Flow Control Chutes by

Reverse Engineering for Plant Modernization by 3D Laser Scanning

scan, process, model , analyze, Implement

Collection of Available Data

All available Conventional Datas are collected from the Plant Resources and documented before the start of site set up for 3D Laser Scanning.

This includes Plant layout drawings, Equipment list, and any other relevant data which would provide additional help during 3D modeling after cloud processing.

Site Preparation and Planning

For more accurate and clear reproduction of plant and equipments, a cleaner envirnment is always desirable free of snow, excessive dust etc. A good houseclening would give better results. Identify locations of target placements and log them before scanning.

3D Laser Scanning and Processing

Once the Site Preparation and procedure is planned, the 3D scnning will be carried out followed by post processing. The Cloud Points after registraion is brought in to 3D modeling software and cleaned up.

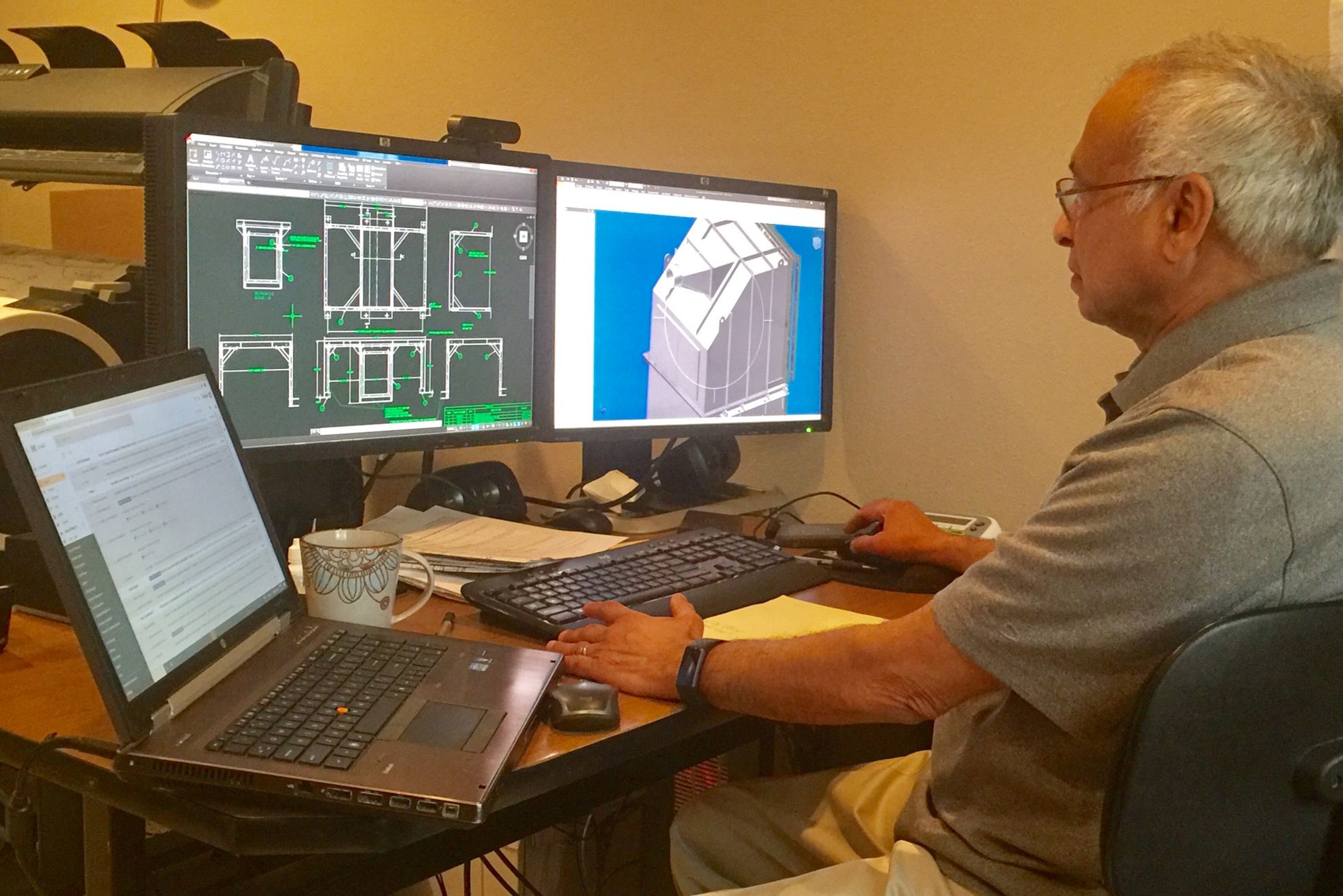

The 3D Design activities starts at this juncture. The Engineer can Analyze the data and implement upgrades after the 3D models takes final shape.

DEM Analysis and Generation of 3D Models and Drawings from Scanned Cloud points

3D models are modified for upgrades and DEM Analysis is carried out on the successful model for the best flow characteristics. From the final 3D solid Models nesecessary drawings are generated for Data Storage for later retrieval or for Manufacturing Drawings for plant upgrade.

Professional Material Handling Solutions. Highly experienced & equipped personnel